Repair and maintenance

MAINTENANCE

Nippon Gear’s products are sometimes used in harsh environments. For the safe operation of plants and other facilities, it is necessary to maintain the original quality, precision, and function of products for a long period of time. To optimize the operating efficiency of equipment and to ensure reliability and safety, Nippon Gear offers maintenance services nationwide. Our service representatives have typical advanced maintenance technology and experience in electric, oil, chemical, gas, and water and sewage system facilities.

Maintenance of actuators

Valve actuators are susceptible not only to use and environmental conditions but also to age deterioration of the electric components, bearings, grease, and sealing materials. To continue normal operation without interruption, periodic inspections and maintenance are required.

Inspection

-

Levels A, B and C inspections

Level A inspection: Simple inspection at site (Periodic inspection every year)

Detail

Level B inspection: On-site detailed inspection (Inspection every three to five years)

Level C inspection: Factory inspection (Inspection every seven to ten years)

Diagnosis

-

MAC valve actuator diagnostic device

MAC diagnosis is an advanced motor-operated valve diagnosis service developed by Nippon Gear. It enables the repair of specific parts without unnecessary disassembling the valves.

Detail -

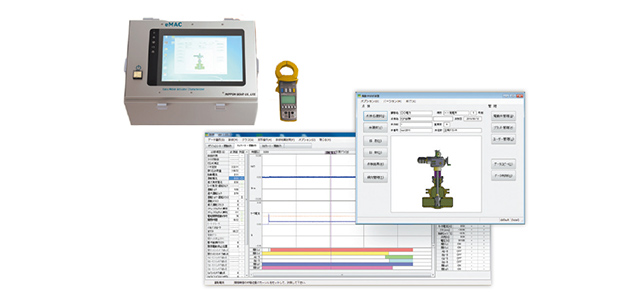

eMAC simplified valve actuator diagnostic system

The eMAC diagnosis is a simplified diagnosis conducted only through current measurement at the control center. The diagnosis can be made without visiting the site.

Detail -

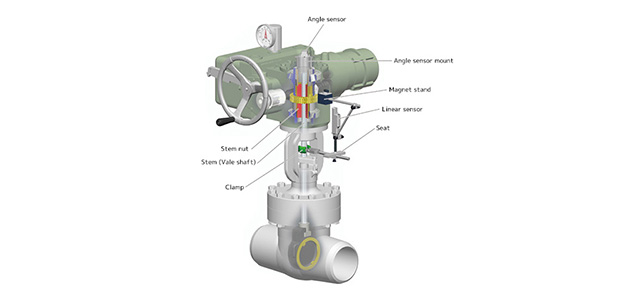

SAM automatic stem nut abrasion measurement system

The SAM automatic stem nut abrasion measurement system can measure the abrasion of the thread of a stem nut mounted in motor-operated valve actuators automatically, and accumulate measurement data.

Detail

SAM is a diagnosis specialized in stem nuts. Measuring the abrasion of the stem nuts (threads) without decomposition and accumulating measurement data will manage the tendencies of time for replacement. -

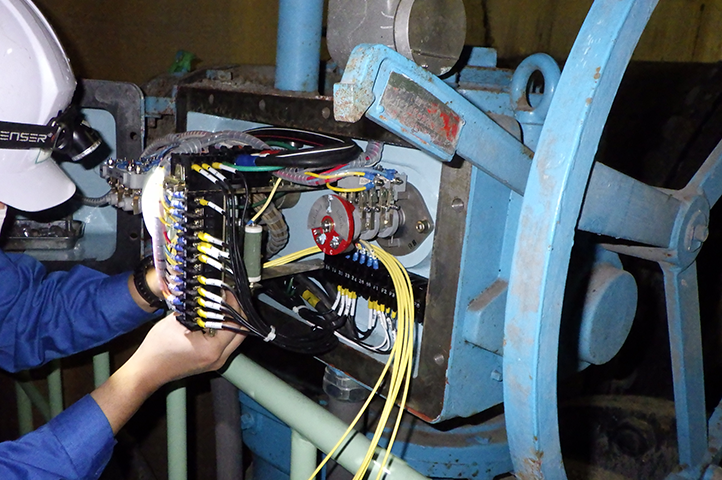

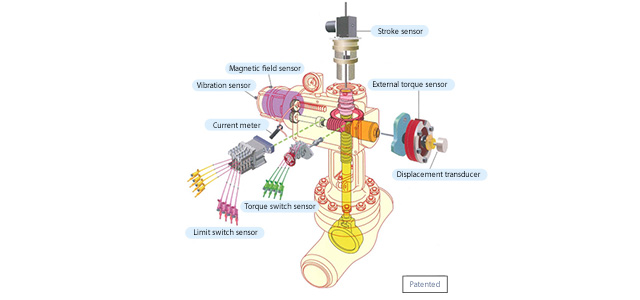

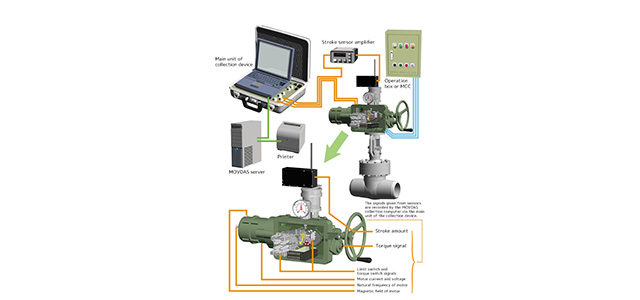

MOVDAS device for diagnosing motor-operated valves in operation

The MOVDAS device for diagnosing motor-operated valves in operation is a motor-operated valve diagnostic device combining state-of-the-art sensor technology and computer technology. Because this device can diagnose every part, it can manage the tendencies of motor-operated valves in a comprehensive manner.

Detail

Modification

-

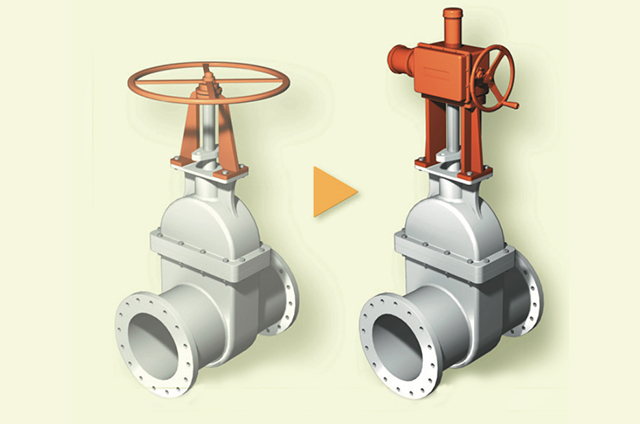

Modification

Replacing a part of an existing manual valve changes it into an electric type easily.

Detail

Maintenance of precision machines

-

Maintenance of other gearboxes (mixers, cooling tower fandrives)

We also offer maintenance and inspection service suitable for various kinds of individual products of ours other than valve actuators.

Detail

We propose the most appropriate inspection items and replacement parts based on basic information, such as usage conditions and the age of the service provided in advance.

We take advantage of our expertise as a manufacturer and ensure safe performance after maintenance through precise and appropriate assembly, use of our genuine parts, and performance inspection equivalent to the one performed at the time of the shipment of new product.