Repair and maintenance

MAINTENANCE

Levels A, B and C inspections

Outline

Level A inspection

An annual inspection done on-site with the valve actuator attached to the valve. We will inspect/clean the wiring/electric parts, check for any looseness, damage, breakage, and inspect the oil/lubricant inside the actuator. Lastly a test run is carried out on site.

Level B inspection

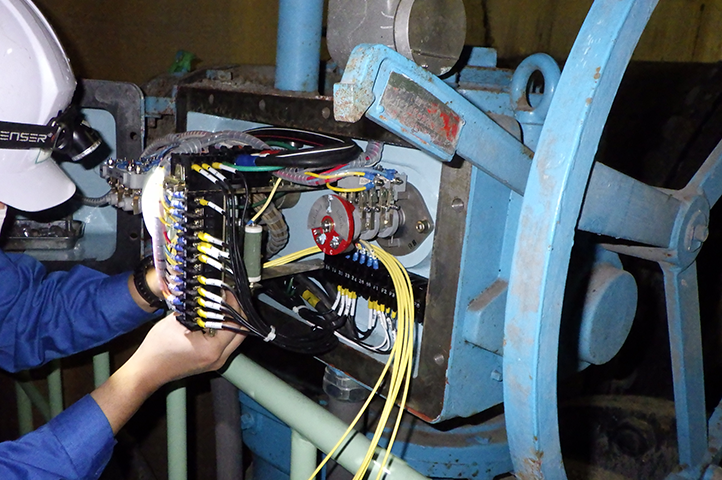

An inspection done every three to five years on-site with the valve actuator attached to the valve. In this inspection, which is intended to disassemble the valve actuator as much as possible, the motor is dismounted to inspect the teeth of the gears, and the functions of electric parts, such as the limit switch and torque switch.

Level C inspection

The valve actuators are dismounted and then transported to our factory. This is an inspection done once every seven to ten years in which the valve actuators are disassembled completely to check the functions, clean and wash the gears, and replace parts and the grease inside. After the overhaul, the valve actuators are repainted and a function test is carried out. The Valve actuators are reinstalled on-site.

About the function test

There are many advantages to a maintenance inspection conducted by the manufacturer, and the function test is one of them. By conducting a thorough overhaul in our own factory and running load characteristic tests and test runs, we will return the parts in perfect condition.

Features

Level A inspection

- – An inspection that can be implemented on-site with the valve actuator attached to the valve.

- – Check of the deterioration status of lubricant and electric components.

- – Check of appearance

Level B inspection

- – An inspection that can be implemented on-site with the valve actuator attached to the valve.

- – The motor can be dismounted to inspect the teeth of the internal gear.

- – Electric components and lubricant are replaced on-site.

Level C inspection

- – Inspection and maintenance performed at our factory with the valve actuator dismounted from the valve.

- – Functional check of the gears can be performed through an overhaul.

- – Implementation of cleaning, washing, and replacement of mechanical parts, electrical components, and lubricant.

- – Implementation of function test (load characteristic tests and test runs).

点検項目

| Level A inspection | Level B inspection | Level C inspection |

|---|---|---|

|

Inspection items include the following in addition to the Level A inspection items:

|

Inspection items include the following in addition to the Level A and B inspection items:

|