Gear

High-precision cylindrical gear

Outline

The teeth at the precision level of JIS0 or higher can be ensured by grinding the surface of high speed-up cylindrical gears with many teeth and small modules using a gear grinder. This realizes smooth, silent meshing even at a peripheral velocity of 100 m/s or higher. This product is used in a variety of equipment requiring high-speed rotation, such as compressors and power-generating units.

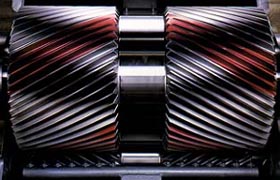

Gears that have two helical gears with different helix directions on the same axis are called double helical gears. The gear surface is ground using a gear grinder. This product is used in rotation devices that require high-speed rotation and because it has rightward and leftward helixes on the same axis, it offsets the thrust force generated and is advantageous in terms of design and use.

Gear grinding dimension chart

| Gear grinder | Maximum tip diameter | 2,000mm |

|---|---|---|

| Maximum face width (spur gear) | 2,020mm | |

| Maximum/minimum pitch | Mod.45/1 | |

| Maximum/minimum number of teeth | No input limit | |

| Maximum helix angle | -45°~+120° | |

| Maximum allowable workpiece weight | 14,000kg | |

| Hobbing machine | Maximum tip diameter | 2,000mm |

| Maximum face width | 1,760mm | |

| Maximum pitch | Mod.30 | |

| Maximum/minimum number of teeth | No input limit | |

| Maximum hob diameter | 385mm |