Screw Jack

Usage Examples

Outline

Nippon Gear’s jacks are actively used in various environments, including liquid crystal, semi-conductor, steel, construction machinery, and machine tool industries. Recently, players in other industries, which traditionally used hydraulic jacks, have become aware of the features and benefits of mechanical/electric jacks, and increasingly adopted Nippon Gear’s jack series.

The following are some examples of application.

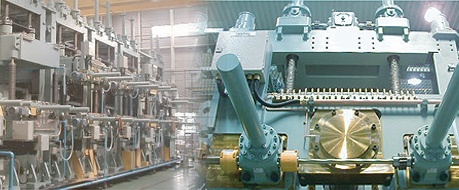

Pipe Molding Machine

For the upper and lower parts of the machine, 4 jacks/1motor are used; and for the left and right parts, 2 jacks/1 motor are used, ensuring machine synchronization by using connecting shafts and gear boxes. For each jack, the jack is fixed, and the shaft end is supported (flange). By adjusting the positions of the screw shafts, pipe molding is carried out.

(The jacks are used in places where the screw shaft covers are sticking out in the photo.)

Conveyer systems

While the jacks are supported (trunnion base), and the shaft ends are supported (clevis), the jacks incline the conveyor to discharge the gravel.

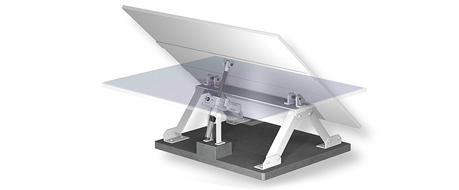

Solar panels

By adjusting the angle of the panels to the position of the sun, the panels have a higher power efficiency compared to fixed panels. The jacks are contributing to new energy and ecology.

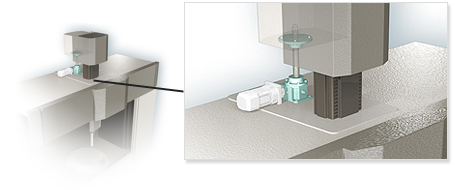

Machining Equipments

Aircraft maintenance

Since the screw jacks have the self-locking function, there is no unexpected fall of the jacks. The jack serves as a reliable tool in assembling and maintaining aircrafts, thus supporting the air safety.

Turntable